There are several types of tests for circuit boards:

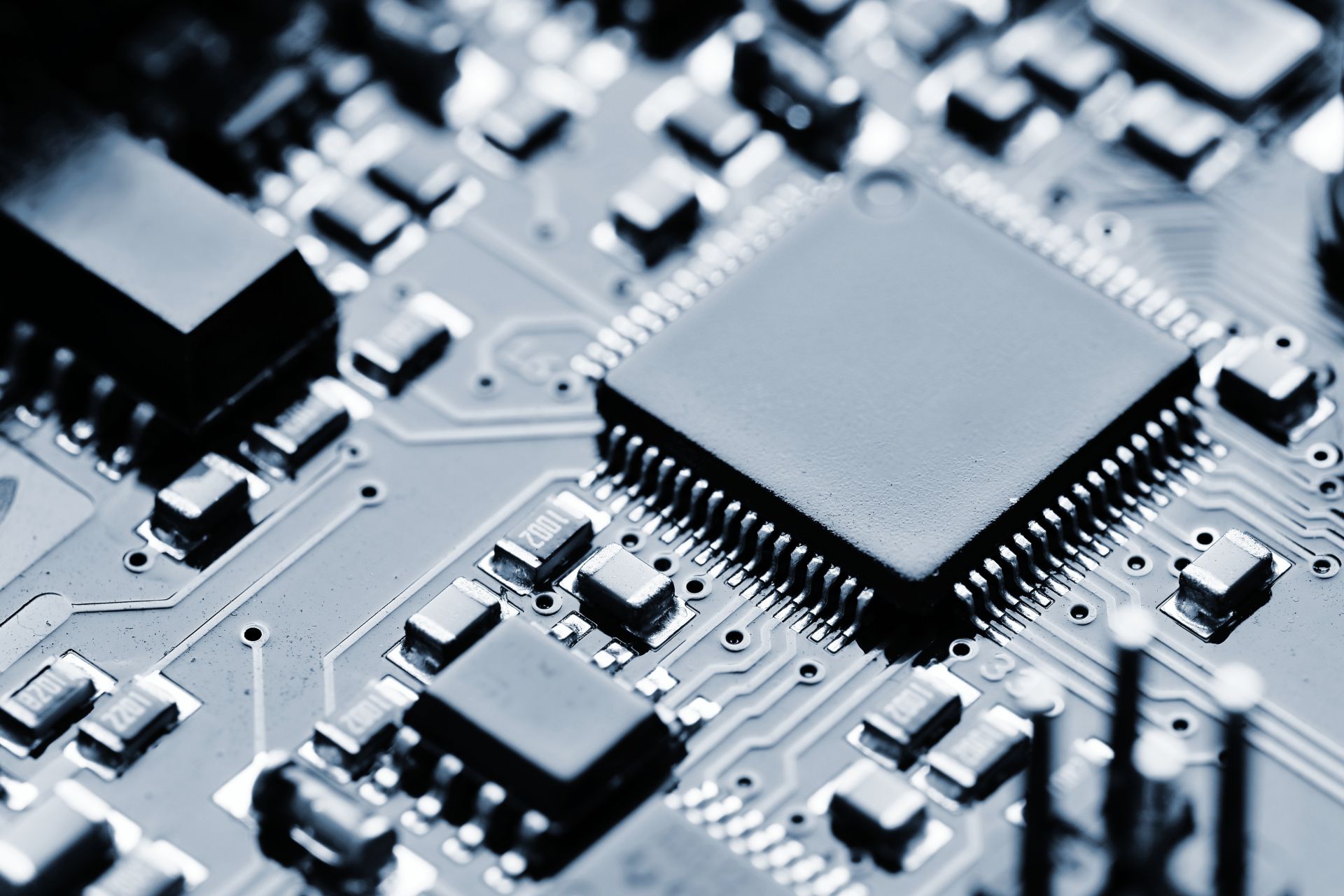

Electrical Testing: This involves checking the electrical connectivity and functionality of the circuit board using specialized equipment. It verifies that all components are properly connected and that the electrical signals pass through the intended paths.

In-Circuit Testing (ICT): ICT is a comprehensive test that checks the individual components and their functionality while they are still on the circuit board. It typically uses test probes to access specific points on the board and applies test signals to measure various parameters.

Functional Testing: Functional testing evaluates the overall performance and functionality of the circuit board by simulating real-world operating conditions. It checks if the board performs as intended and meets the specified requirements.

Boundary Scan Testing: Boundary scan, also known as JTAG (Joint Test Action Group) testing, uses specialized test circuitry built into the ICs (Integrated Circuits) to verify their functionality. It allows for the testing of complex digital circuits and helps diagnose faults in the circuit board.

X-ray Inspection: X-ray inspection is a non-destructive testing method that uses X-rays to inspect the internal structure of the circuit board. It can detect defects such as solder joint quality, component placement, and hidden defects that may not be visible through visual inspection.

Thermal Testing: Thermal testing evaluates the circuit board's performance under different temperature conditions. It assesses its ability to dissipate heat and ensures that it can function reliably within specified temperature ranges.

Environmental Testing: Environmental testing involves subjecting the circuit board to various environmental conditions, such as temperature, humidity, vibration, and shock. This helps assess its durability, reliability, and ability to withstand harsh operating conditions.