PCBs are commonly made using a variety of materials, including:

Substrate Material: The base material of a PCB, often made of fiberglass-reinforced epoxy resin (FR-4) or other types of laminates such as polyimide (PI) or metal core materials like aluminum or copper.

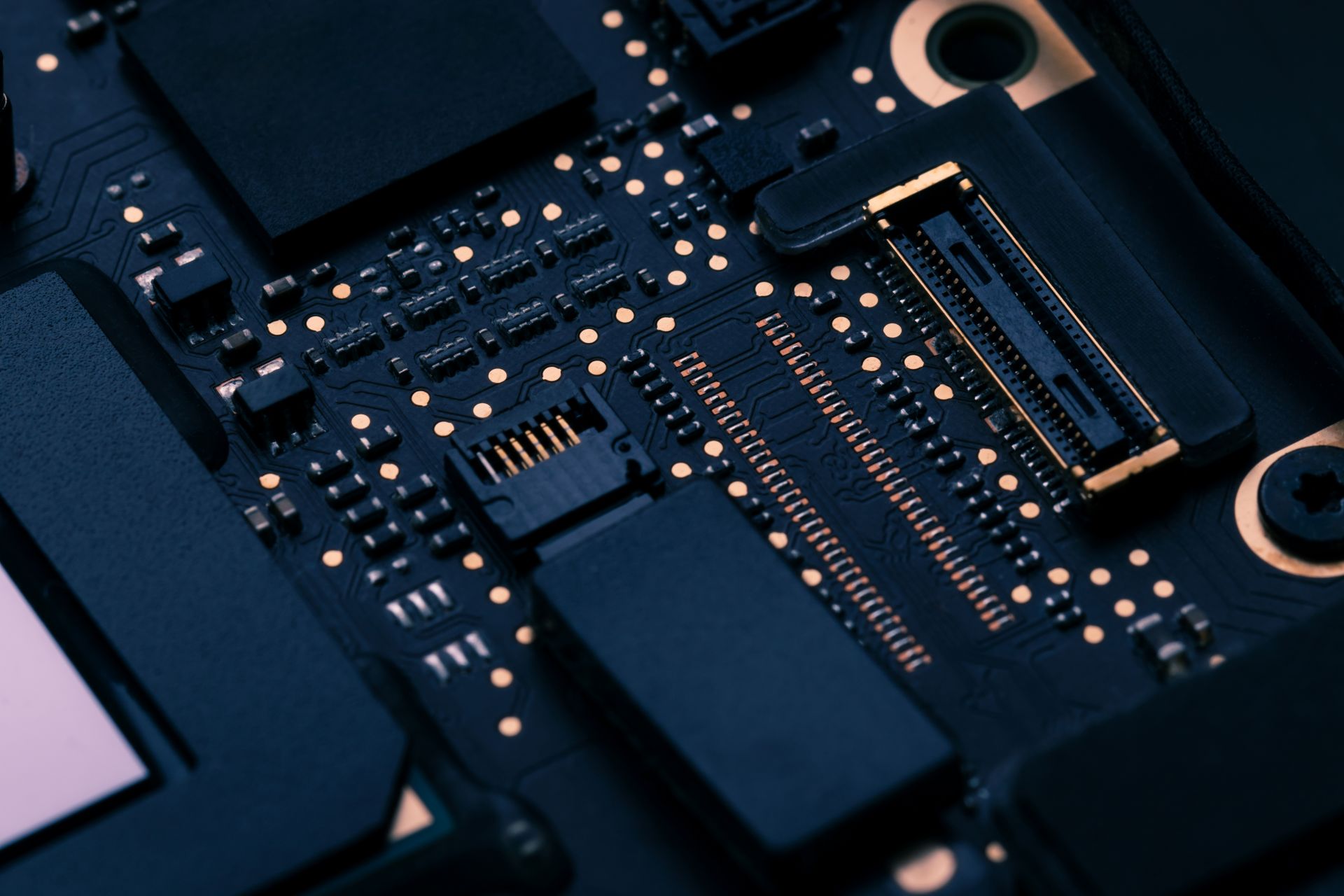

Copper Foil: A thin layer of copper laminated onto the substrate material, used for creating conductive traces and pads on the PCB.

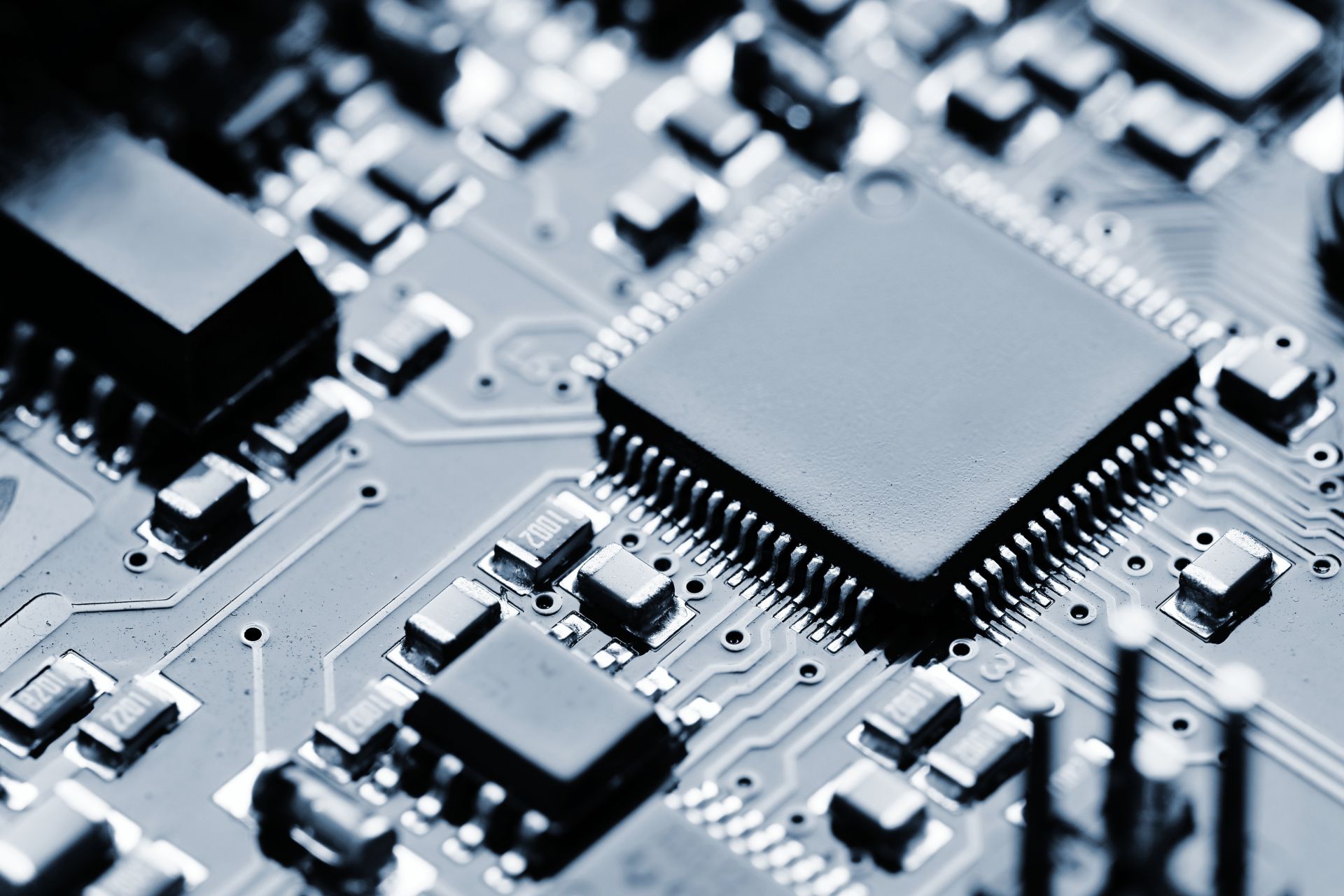

Solder Mask: A protective layer applied over the copper traces to prevent accidental solder bridges and corrosion. It is typically made of epoxy-based polymers in various colors, such as green, red, or blue.

Silkscreen: A layer of ink printed on the PCB's surface to add component markings, reference designators, logos, and other identification information.

Surface Finish: The coating applied to the exposed copper surfaces to protect them from oxidation and facilitate soldering. Common surface finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), OSP (Organic Solderability Preservative), and immersion tin or silver.

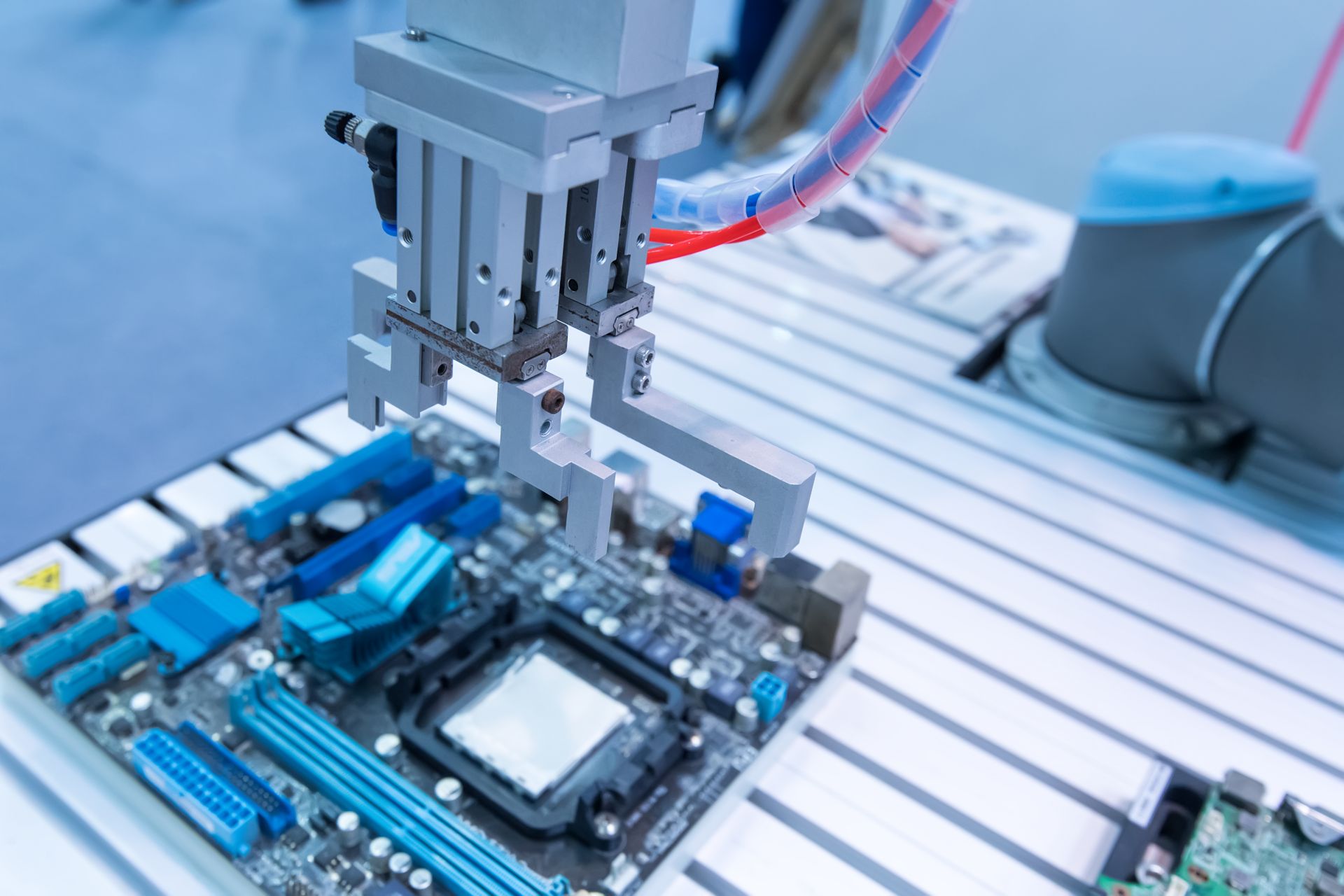

Solder Paste: A mixture of solder alloy particles and flux used during the assembly process to create solder joints between components and the PCB.

Electronic Components: Various components, such as resistors, capacitors, integrated circuits, connectors, and other active and passive devices, are mounted on the PCB to create the desired electronic circuitry.